Salt Spray Corrosion Test

Salt spray corrosion test. It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion. Cyclic Corrosion Test Salt Spray Chambers. I mention that salt spray is a continuously wet test and in the past has been used mainly for process control checks as one of your respondents mentioned.

Standardized salt spray or fog testing performed under ASTM B117 is an accelerated corrosion method applied to measure the relative corrosion resistance of exposed coated metals in high temperatures. The reason is that the salt spray test offers numerous advantages. Cyclic Corrosion Test Chambers.

As a rule of thumb polymeric coatings in 240h salt spray test at 35C will age similarly to a 2-year. Some form of the salt spray test has been in existence since 1914. Salt spray testing is a laboratory simulation of a corrosive saline environment.

Laboratory salt spray testing has been used for many years to accelerate natural atmospheric exposures with limited success. The stressor in these cases is sodium chloride a natural enemy to metal and several alloys. This corrosion test is intended to provide corrosion resistance information on metals and coated metals.

It has become a universal test. The salt spray test is the oldest corrosion test and the most widely used by users of highly corrosion-resistant material. One of the most interesting is that the test is multi-material.

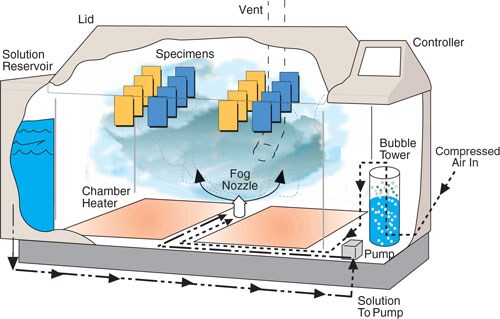

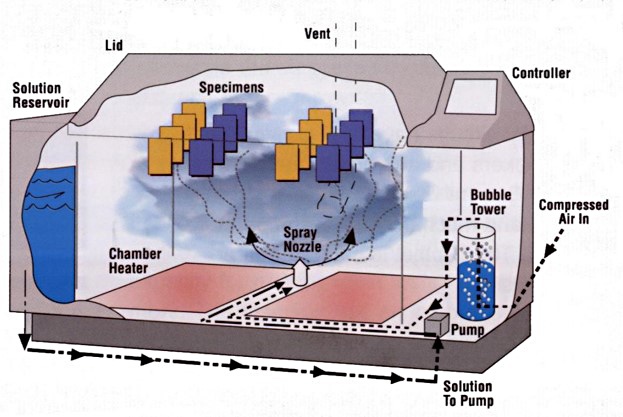

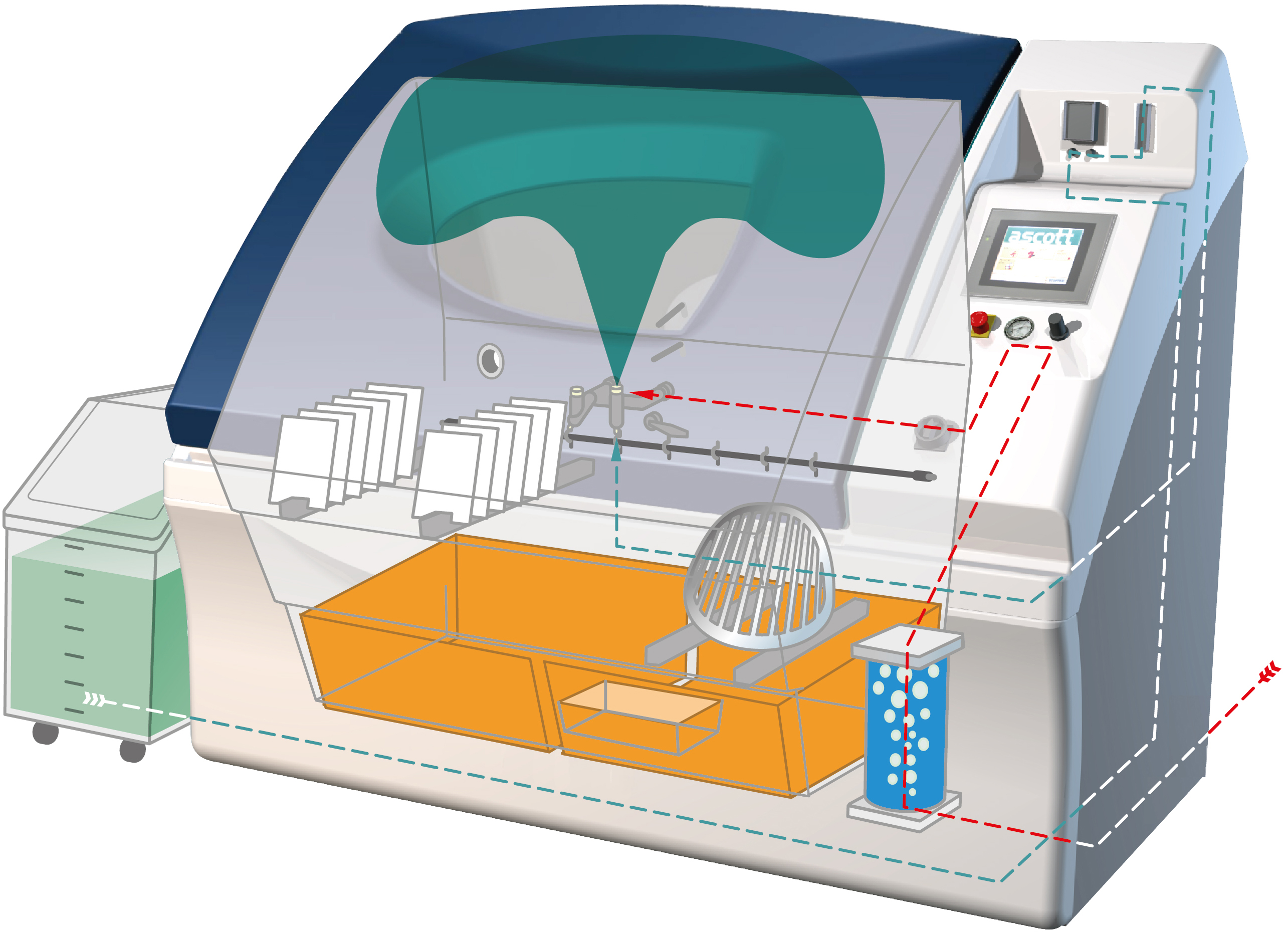

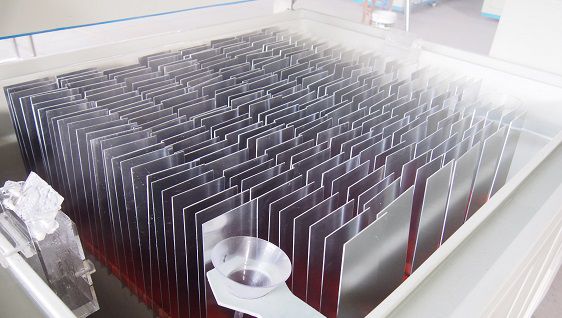

Test specimens were subjected to salt spray testing in accordance with ASTM B117. The Auto Technology Company Cyclic Corrosion Test CCT series of chambers are the industrys most advanced flexible and robust test chambers available anywhere in the world. The ASTM B-117 salt spray test uses a closed testing chamber in which a salt water 5 NaCl solution is atomized by means of spray nozzles using pressurized air.

However this instigated corrosion is accelerated or done in a compressed time frame. Definition - What does Salt Spray Testing mean.

Some form of the salt spray test has been in existence since 1914.

The continuously wet test is probably some indication of corrosion rate in 5 salt solution or some form of general corrosion. The modern mode of testing was conceived in 1939 by AES and ASTM Committee B32 It was hoped that a test employing 20 percent neutral salt spray could be used to predict the corrosion resistance. The reason is that the salt spray test offers numerous advantages. Corrosion testing of four PM stainless steel materials SS-316N1 SS-316N2 SS-316H and SS-434H has been conducted under the auspices of the MPIF Standards Committee. It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion. The salt spray test is the oldest corrosion test and the most widely used by users of highly corrosion-resistant material. Some form of the salt spray test has been in existence since 1914. Its very hard to estimate the acceleration factor and it will be depend on the coating type. The salt spray test is an accelerated corrosion test used to measure the comparative corrosion resistance of materials exposed to a salt spray or salt fog at high temperature.

Its very hard to estimate the acceleration factor and it will be depend on the coating type. I mention that salt spray is a continuously wet test and in the past has been used mainly for process control checks as one of your respondents mentioned. Salt spray testing is a laboratory simulation of a corrosive saline environment. Its very hard to estimate the acceleration factor and it will be depend on the coating type. The test is usually terminated and the hours recorded when the surface of the sample has been penetrated by the corrosive effects of the salt environment. It is used as an accelerated means of testing the ability of surface coatings to withstand atmospheric corrosion. Some form of the salt spray test has been in existence since 1914.

I have just gone through your blog......your information is so valuable. Thanks for sharing this information. ABS Instruments Pvt. Ltd. is a Thirty Years old company that supplies the best in materials testing equipment from all over the world to our customers in India.Salt Spray Chamber

ReplyDeleteThanks for sharing! I like it. It looks good.

ReplyDeletehttps://www.testextextile.com/product/salt-spray-tester-tu380/

DeleteThis comment has been removed by the author.

ReplyDelete